demister pad

Demister pad, also known as a mist eliminator or demister separator, is a device used in various industrial processes to remove liquid droplets or mist from a gas stream. It consists of a mesh or a series of layers made from materials like metal, plastic, or fiberglass. The primary purpose of a demister pad is to separate liquid particles (usually small droplets) from a gas stream, ensuring that the gas leaving the system is free from these entrained liquids.

Demister pads come in various configurations, including wire mesh pads, vane-type separators, and fiber-bed demisters, among others. The choice of demister pad depends on the specific application and the properties of the gas and liquid being processed. These devices play a crucial role in ensuring the quality and efficiency of various industrial processes while minimizing environmental impact.

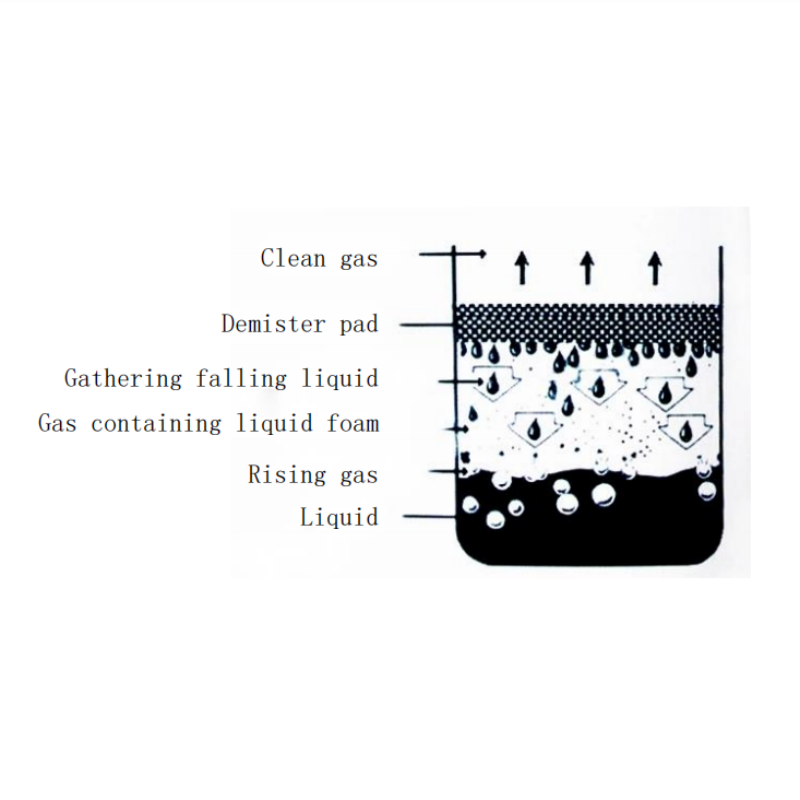

WORKING PRINCIPLE

When gas containing mist ascends through a mesh at a certain velocity, due to the inertia of the mist, mist particles collide with the fine wires of the mesh and adhere to the wire surfaces. The diffusion of mist on the wire surfaces and the gravitational settling of mist particles cause the mist to coalesce into larger liquid droplets as they flow along the wires toward the intersection of two wires.

The wettability of the wire surfaces, the liquid’s surface tension, and the capillary action of the wires lead to the continuous growth of the droplets until they become sufficiently large. When the accumulated droplets reach a size where their self-generated gravity overcomes the combined forces of the gas’s upward motion and the liquid’s surface tension, the droplets separate from the wires and fall. After passing through the mesh demister, the gas is essentially free from mist.

Materials

SS304、SS304A、SS316、SS316L、Monelse、PP、PEFT、etc.

SS304 Demister Pad

PP-Demister Pad

PTFE-Demister Pad

Shaped

Application

Petrochemical and Oil Refining: They are used to separate liquid droplets from gas streams in distillation columns, fractionators, and other process equipment.

Chemical Processing: Demister pads help maintain the purity of gases in chemical reactors and scrubbers.

Power Plants: They are used in power plants to remove moisture from flue gases, reducing corrosion and improving the efficiency of downstream equipment.

Oil and Gas Production: Demister pads are employed to separate oil and water droplets from gas streams in production separators.

Air Pollution Control: In environmental applications, they can be used to remove particulate matter and aerosols from exhaust gases before releasing them into the atmosphere.