Wedge Wire Screen

Wedge wire screen, also known as a wire-wrapped screen, is a type of filtering or screening element used in various industrial processes, particularly in the field of water treatment, wastewater treatment, and solid-liquid separation. It is designed to effectively separate solids from liquids or to allow the flow of certain materials while blocking others.

In summary, wedge wire screens are versatile filtration and separation devices used in various industrial applications. They are known for their durability, efficiency, and customization options, making them an essential component in many industries where solid-liquid separation or material filtration is required.

Materials

SS304、SS304A、SS316、SS316L、Monelse、etc.

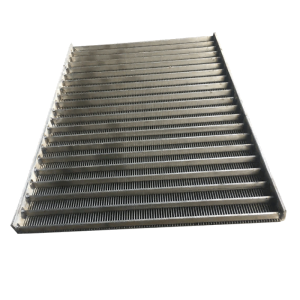

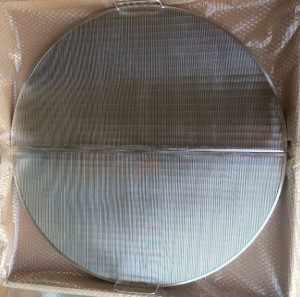

Wedge wire screens can have various shapes, including flat, circular, and curved. In any case, the shapes are diverse, and their functions vary. They can also be customized according to specific applications and requirements. These different shapes of screens can meet various filtration and separation needs. Manufacturers can customize wedge wire screens according to specific requirements to ensure optimal performance in particular industrial processes. This flexibility makes wedge wire screens essential filtration and separation devices suitable for a wide range of applications.

Construction: The primary component of a wedge wire screen is a set of parallel wires or rods that are wrapped or welded onto support rods. These wires are typically made from stainless steel or other corrosion-resistant materials. The wire-wrapped structure creates a continuous slot or V-shaped wedge profile along the length of the screen.

Slot Openings: The shape and size of the wedge wire slots can vary depending on the specific application and requirements. The slot openings can range from fine to coarse, and they play a crucial role in determining the filtration or separation capabilities of the screen.

Support Structure: The support rods are positioned perpendicular to the wrapped wires and provide structural integrity to the screen. They also help maintain the precise spacing and alignment of the wires, ensuring uniform slot openings.

Function: Wedge wire screens are used to filter or separate materials in various applications, including water intake screens, wastewater treatment, pulp and paper processing, mining, food and beverage production, and more. They can remove solids from liquids, support resin beds in ion exchange processes, and serve as dewatering screens in various industries.

Customization: Wedge wire screens can be customized to meet specific filtration requirements, including slot size, wire diameter, and screen dimensions. This allows them to handle a wide range of applications and effectively filter different types of materials.

Advantages: Wedge wire screens offer several advantages, including high mechanical strength, corrosion resistance, low maintenance requirements, and the ability to withstand high temperatures and pressures. They also provide excellent filtration efficiency and are less prone to clogging compared to some other filtration methods.

Cleaning: Depending on the application, wedge wire screens may require periodic cleaning to remove accumulated solids or debris. Cleaning methods can include backwashing, brushing, or chemical cleaning, depending on the nature of the filtration process and the materials being filtered.