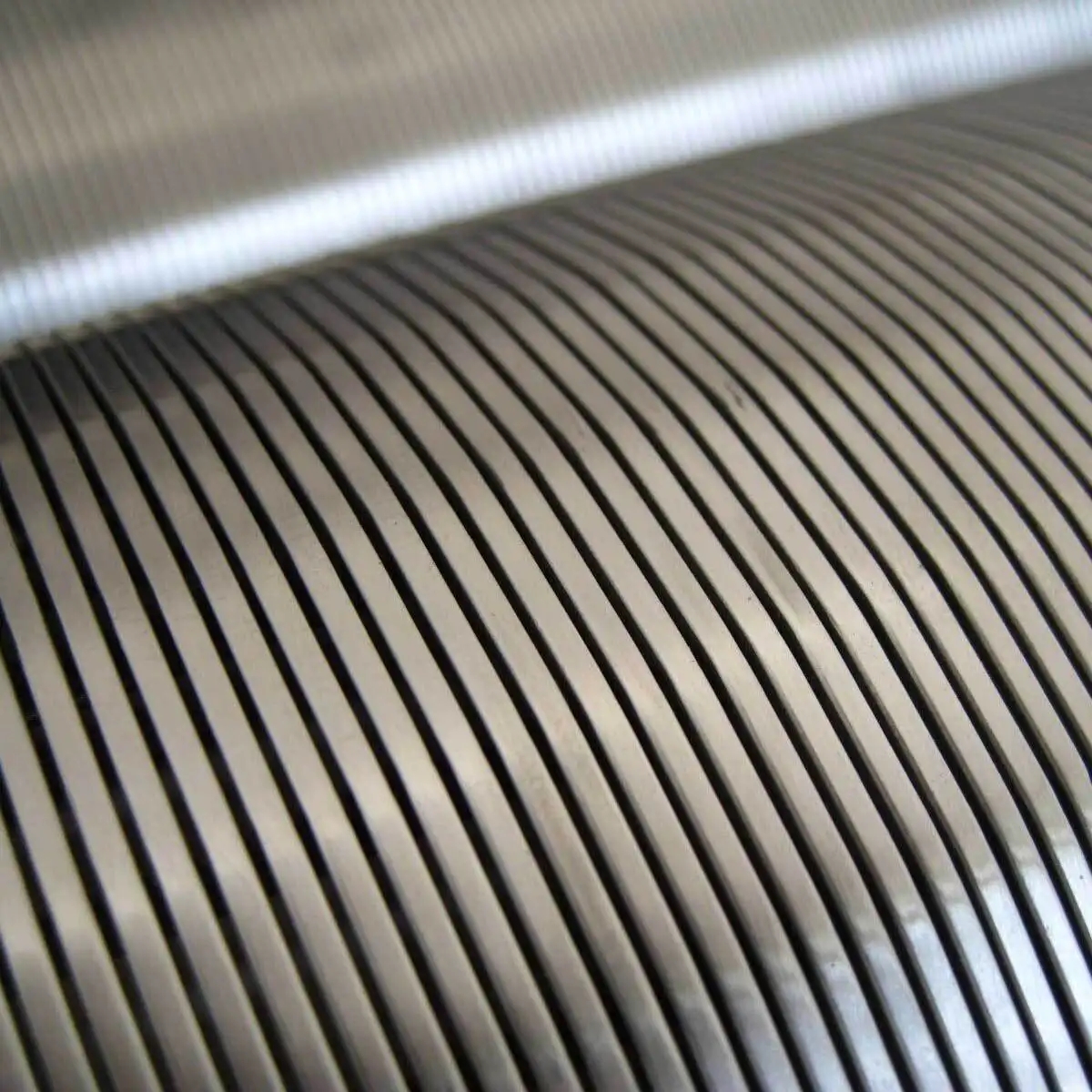

Wire Wrapped Screen

Wire wrapped screen, often referred to as a wire-wrapped well screen or simply a wire wrap screen, is a type of filter or screen used in water wells and other applications to filter out sand, gravel, and other fine particles while allowing water or other fluids to flow through. These screens are commonly used in groundwater extraction and oil and gas drilling.

Wire wrapped screens play a crucial role in maintaining the integrity and efficiency of water wells and oil/gas wells, ensuring that clean fluids are extracted while preventing the ingress of unwanted materials. Their design can be tailored to meet the needs of specific applications, making them a versatile solution for various industries.

Materials

SS304、SS304A、SS316、SS316L、Plain Carbon Steel、etc.

Filter Nozzle

Screen Pipe

Screen Tube For Oil Well

WedgeWire Mesh

Components Of A Wire Wrapped Screen

Wire Wrap: The central component of a wire wrapped screen is a cylindrical or conical screen made of wire. This wire is typically made of stainless steel or other corrosion-resistant materials. The wire is wrapped or wound around a support rod or base pipe to form a continuous spiral pattern. The size and spacing of the wire wraps can vary depending on the specific application and the desired filtration characteristics.

Support Rod/Base Pipe: The wire wrap screen is usually supported by a central rod or base pipe, which provides structural integrity to the screen. The base pipe can be perforated to allow fluid to enter the screen.

Slot Openings: The gaps between the wire wraps create slot openings through which the fluid can pass. The size of these slot openings can be customized to control the particle size that is allowed to pass through the screen. The selection of slot size is critical to ensuring effective filtration.

End Fittings: Wire wrapped screens are typically equipped with end fittings that allow them to be connected to the well casing or other components of the well. These fittings can be threaded or welded, depending on the application.

Materials: The choice of materials for both the wire and the support rod/base pipe is crucial to ensure the screen’s durability and resistance to corrosion. Stainless steel is a common choice because of its corrosion resistance and strength.

Features

Efficient Filtration: They effectively filter out sand, gravel, and fine particles while allowing the passage of water or other fluids.

Structural Strength: The wire wrap and support rod/base pipe construction provides strength and stability, making them suitable for deep wells and high-pressure environments.

Customization: Slot size, wire material, and screen diameter can be customized to suit specific well conditions and filtration requirements.

Corrosion Resistance: Stainless steel construction ensures long-lasting performance in corrosive environments.

Easy Installation: They are relatively easy to install and can be connected to well casings and other components with compatible fittings.