Wire mesh is a versatile material widely used in industrial, architectural, and technological applications. However, not all wire meshes are created equal. Two common types—woven wire cloth and knitted wire mesh—differ significantly in their manufacturing processes, structural properties, and use cases. In this blog, we’ll explore these differences to help you choose the right solution for your needs.

- Manufacturing Processes

Woven Wire Cloth

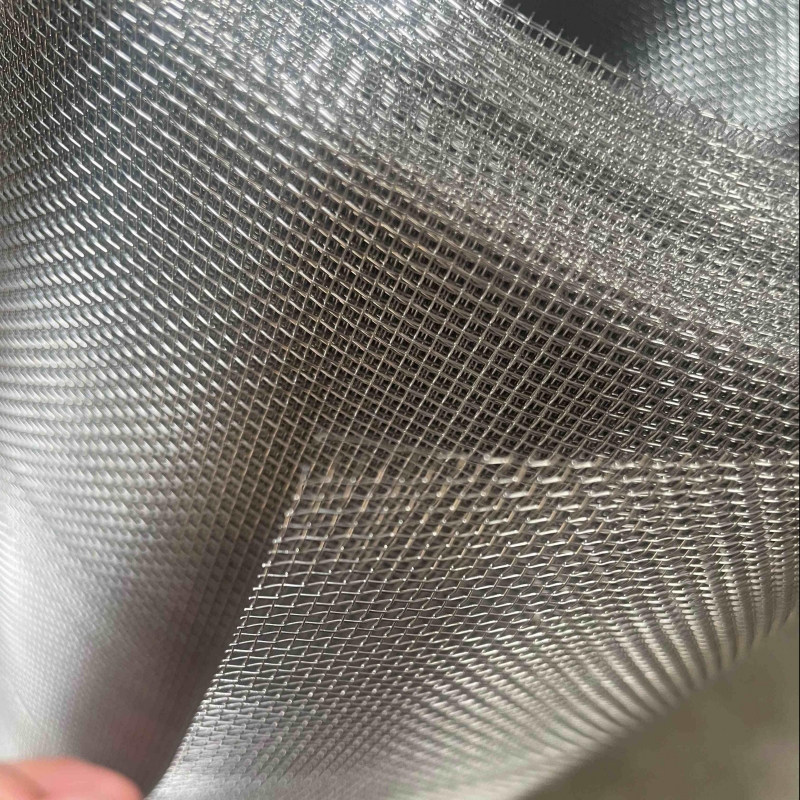

Woven wire cloth is produced using a traditional weaving technique similar to textile manufacturing. Metal wires (stainless steel, copper, aluminum, etc.) are interlaced on industrial looms in two primary directions:

Warp wires: Longitudinal wires held under tension.

Weft wires: Transverse wires woven over and under the warp wires.

Common weave patterns include plain weave (simple over-under pattern), twill weave (diagonal pattern for added strength), and Dutch weave (fine mesh with high filtration efficiency). The result is a rigid, uniform grid-like structure with precise openings.

Knitted Wire Mesh

Knitted wire mesh is created using a loop-forming process, akin to knitting fabrics. Metal wires are fed into knitting machines, where needles interloop the wires into a series of connected coils. This creates a flexible, three-dimensional structure with inherent elasticity. Unlike weaving, knitting does not require warp and weft alignment, resulting in a looser, more porous mesh.

- Structural Characteristics

Feature Woven Wire Cloth Knitted Wire Mesh

Strength & Rigidity High tensile strength, rigid structure Flexible, stretchable, and compressible

Porosity Controlled, uniform openings Irregular, highly porous structure

Surface Texture Smooth, flat surface Textured, bumpy surface due to loops

Thickness Consistent, depending on wire diameter Variable, often thicker due to layered loops - Applications

Woven Wire Cloth

Filtration & Sieving: Used in precision sieves, filter screens, and particle separation due to its uniform openings.

Security & Safety: Ideal for grilles, machine guards, and fencing.

Architecture: Decorative panels, sunshades, and façades requiring rigidity.

Electronics: EMI/RFI shielding in sensitive devices.

Knitted Wire Mesh

Fluid/Gas Flow Control: Used in demisters, scrubbers, and fuel cell components where high porosity is critical.

Sealing & Cushioning: Gaskets, seals, and vibration-damping pads in automotive/aerospace industries.

Thermal Insulation: Heat-resistant blankets or insulation layers in high-temperature environments.

Noise Reduction: Acoustic dampening in industrial equipment.

- Pros and Cons

Woven Wire Cloth

✅ Pros: High precision, durability, and load-bearing capacity.

❌ Cons: Less flexible; edges may fray if not properly hemmed.

Knitted Wire Mesh

✅ Pros: Excellent flexibility, lightweight, and shock absorption.

❌ Cons: Lower tensile strength; not ideal for fine filtration.

- Choosing the Right Mesh

Opt for woven wire cloth if your project demands rigidity, precision, or controlled filtration (e.g., sieving powders or protecting machinery).

Choose knitted wire mesh for applications requiring elasticity, high porosity, or cushioning (e.g., sealing systems or noise reduction).

Conclusion

While both woven wire cloth and knitted wire mesh serve as solutions for filtration, protection, and structural support, their distinct manufacturing methods lead to vastly different performance profiles. Understanding these differences ensures you select the optimal material for your technical or industrial requirements.